For centuries, the process of creating a physical object was a slow, expensive, and often wasteful endeavor. A designer would sketch a concept, a craftsman would build a prototype, and a manufacturer would use a complex and rigid assembly line to produce the final product. Today, that paradigm is being shattered by a new, transformative force: 3D printing, or additive manufacturing. This is not just a technological upgrade; it is a fundamental reimagining of how we design, create, and consume physical goods. By building an object layer by layer from a digital file, 3D printing is democratizing manufacturing, accelerating the pace of innovation, and unlocking a new universe of design possibilities that were once limited by the constraints of traditional production methods. This comprehensive article delves into the profound impact of 3D printing on product design, exploring the foundational principles that are driving this revolution, the diverse applications that are already reshaping industries, and the immense opportunities and critical challenges that lie ahead as we move from a world of mass production to a world of personalized, on-demand creation.

Historically, the design-to-production pipeline was a linear and often-inflexible process. A designer would have to create a design that was suitable for a specific manufacturing process—for example, a design that could be molded, cut, or cast. The time and cost of creating a single physical prototype were often prohibitive, a major barrier to a rapid and iterative design process. 3D printing shatters this paradigm. It allows a designer to create a physical object directly from a digital file, a process that is both faster and more affordable. A designer can now create a new product, print a prototype in a matter of hours, and then refine the design based on the physical feedback. This rapid iteration cycle, from a digital file to a physical object, is a game-changer. It is a powerful catalyst that is enabling a new class of designers and entrepreneurs to bring their ideas to life, from a small startup in a garage to a major corporation in a research and development lab.

The global interest in 3D printing is skyrocketing, with new technologies and new materials being developed at a breathtaking pace. The convergence of powerful new technologies—from high-resolution 3D scanners and sophisticated design software to a new generation of high-speed and multi-material 3D printers—is making a new era of on-demand, personalized manufacturing not just a possibility, but a necessity for a competitive and innovative future. From a 3D-printed car chassis that is stronger and lighter than a traditional one to a 3D-printed prosthetic that is custom-made for a single patient, the applications are as diverse as they are profound. This is more than a technological shift; it is a profound philosophical one, where we are beginning to redefine our relationship with our physical possessions, moving from a world of a mass-produced, one-size-fits-all product to a world of a personalized, custom-made one. The 3D printing revolution is here, and it is the new blueprint for a more innovative, more sustainable, and more human-centered world.

The Pillars of Additive Manufacturing

The power of 3D printing is not a single piece of technology but a sophisticated and integrated philosophy that is built on a set of foundational principles that seek to use a new kind of manufacturing to create a new kind of product.

A. Additive Manufacturing and Layer-by-Layer Creation

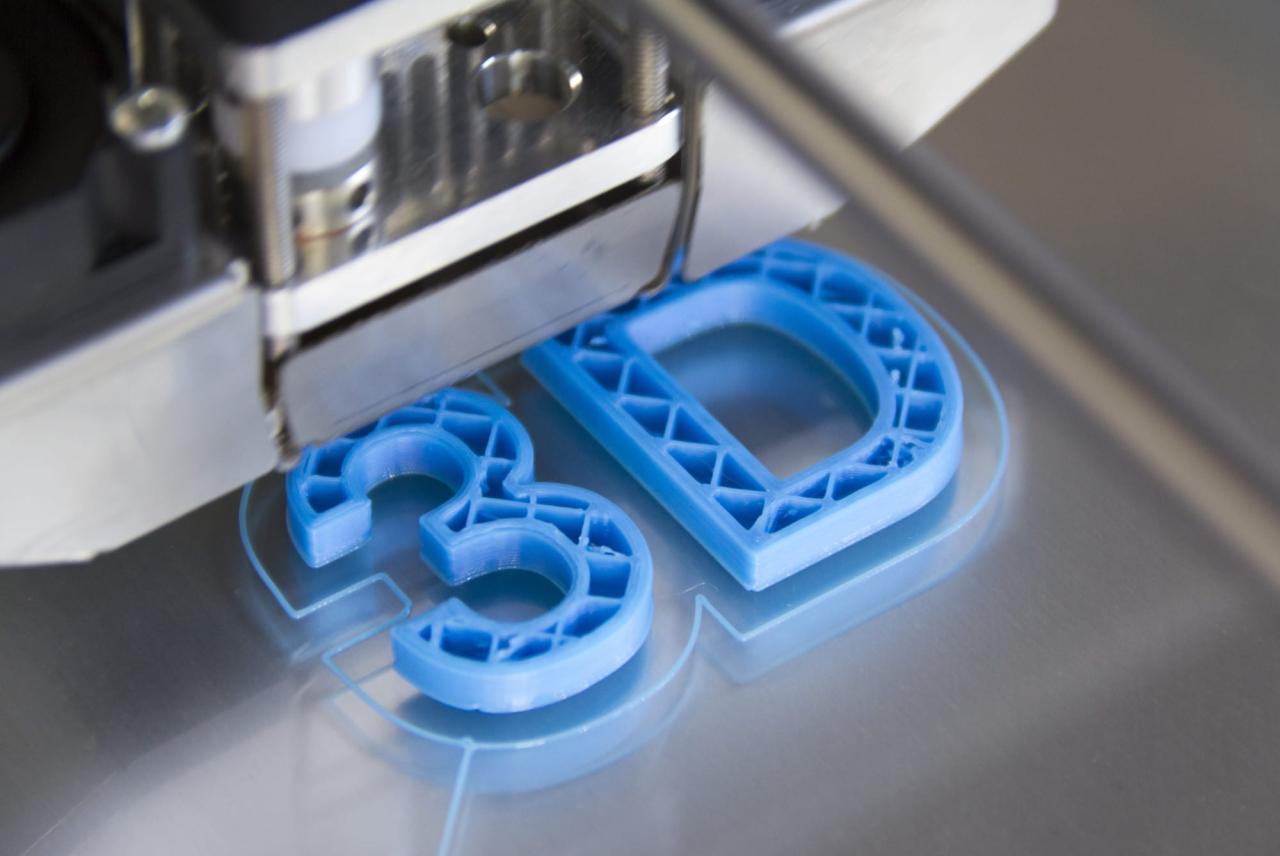

The most obvious and direct principle of 3D printing is additive manufacturing, the process of building a three-dimensional object by adding successive layers of material. This is a fundamental shift from traditional “subtractive” manufacturing, which involves cutting or carving a material to create a final shape. The additive nature of 3D printing means that a designer can create a complex geometry, with a hollow interior or a lattice structure, that would be impossible to create with traditional methods. This allows for a new level of creativity, a new kind of design that is not constrained by the limitations of a mold or a milling machine. This is a shift from a design that is a result of a manufacturing process to a design that is a a direct expression of a creator’s imagination.

B. The Direct-to-Digital Workflow

In a world of 3D printing, the design-to-production pipeline is a direct-to-digital workflow. A designer can create a 3D model of a product in a design software, and then send that file directly to a 3D printer. The printer will then build the physical object, a process that can take a few hours to a few days, depending on the complexity of the design. This eliminates the need for a physical prototype, a long and expensive process that was a major barrier to innovation. This is a shift from a long and a linear design process to a rapid and an iterative one, where a designer can create a new product, test it, and refine it in a matter of hours.

C. The Freedom of Complex Geometry

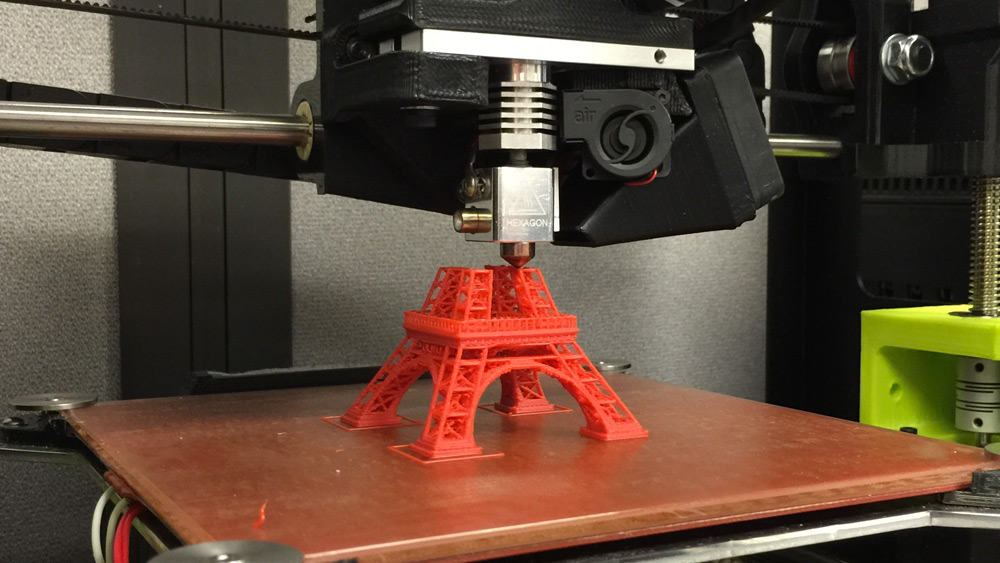

The principles of 3D printing are a celebration of complex geometry. A designer is no longer constrained by the limitations of a traditional manufacturing process. A design can have a hollow interior, a complex lattice structure, or a unique organic shape that would be impossible to create with a mold or a milling machine. This allows for a new kind of design that is not just aesthetically pleasing but also functionally superior. A car part with a lattice structure, for example, can be both lighter and stronger than a traditional one. This is a shift from a design that is a compromise to a design that is a perfect expression of a form and a function.

D. The Power of On-Demand and Personalized Manufacturing

The most profound principle of 3D printing is its ability to create a world of on-demand and personalized manufacturing. A product is no longer a mass-produced, one-size-fits-all object. It is a custom-made, personalized object that is built for a single person. A doctor, for example, can create a 3D-printed prosthetic that is custom-made for a single patient. An entrepreneur can create a new product and print it on demand, without the need for a massive factory or a large inventory. This is a shift from a world of a mass-produced product to a world of a personalized and a custom-made one.

Applications and Benefits of 3D Printing

The principles of 3D printing are being applied to a wide range of industries, creating tangible benefits for creators and a unique experience for consumers.

A. Rapid Prototyping and Innovation

In the world of product design, 3D printing is a game-changer for rapid prototyping and innovation. A designer can now create a new product, print a prototype in a matter of hours, and then refine the design based on the physical feedback. This rapid iteration cycle can lead to a faster time-to-market for new products, a significant reduction in cost, and a more innovative and a more creative design process. This is a shift from a long and a linear design process to a rapid and an iterative one.

B. The Customization and Personalization of Products

The power of 3D printing is its ability to create a world of customization and personalization. A consumer is no longer just a passive buyer; they are a co-creator who can customize a product to their specific needs. A consumer, for example, can design a new pair of shoes that are custom-made for their feet, or a new piece of jewelry that is a reflection of their personal style. This is a shift from a world of a mass-produced product to a world of a personalized and a custom-made one, a new kind of a consumer-centric design.

C. The Medical Revolution

In the medical field, 3D printing is a major force for good. Doctors can now create a 3D-printed prosthetic that is custom-made for a single patient, a process that is more affordable, more comfortable, and more effective than a traditional one. A new and a fascinating field within this is bioprinting, where scientists can use a 3D printer to create a three-dimensional living tissue, such as a human ear or a small organ, from bio-ink containing living cells. While still in its early stages, the long-term potential for this technology is to print a custom-made organ for a transplant patient, eliminating the need for a donor.

D. Sustainable and On-Demand Manufacturing

The traditional manufacturing model is incredibly wasteful, with a significant amount of material being discarded in the production process. 3D printing is a more sustainable and a more on-demand manufacturing process. It uses only the material that is needed to create a product, a process that significantly reduces waste. Furthermore, a product is only printed when a consumer orders it, a process that eliminates the need for a massive inventory and a long supply chain. This is a shift from a world of a wasteful and a linear manufacturing process to a world of a sustainable and a circular one.

Overcoming Challenges to a 3D Printed Future

Despite the immense promise of 3D printing, its development is not without significant challenges that must be addressed.

A. The Challenge of Materials and Strength

The traditional manufacturing process, with its use of a wide range of materials and a high level of strength, is a major challenge for 3D printing. The materials that can be used in 3D printing are still limited, and the strength of a 3D-printed object is often a concern. The challenge is to find a way to create a new generation of materials and a new level of strength that can be used to create a wide range of products, from a car part to a building. The development of new and more advanced materials is a critical part of this process.

B. The Challenge of Speed and Scale

While 3D printing is great for a single, custom-made product, its speed and scale are still a major challenge for a mass-produced product. The process of building an object layer by layer can be slow, and the cost of a large-scale 3D printer can be prohibitive. The challenge is to find a way to make 3D printing faster and more affordable, so that it can be used for a wide range of products, from a single, custom-made object to a mass-produced one. The development of new and more efficient 3D printers is a critical part of this process.

C. The Challenge of Copyright and Intellectual Property

In a world where a physical product can be created from a digital file, the issue of copyright and intellectual property is a major concern. A digital file of a product can be easily copied and distributed, a process that can lead to a major loss of revenue for a designer or a company. The challenge is to find a way to create a new legal framework that can protect a designer’s intellectual property in a world of 3D printing. This will require a collaborative effort from governments, industry leaders, and the legal community.

D. The Challenge of a Skills Gap and Education

The principles of 3D printing require a new set of skills, from a deep understanding of design software to a new kind of engineering that can create a product that is both functionally superior and aesthetically beautiful. The challenge of the skills gap is a major hurdle that must be overcome through new educational programs and a focus on retraining the workforce. The designer of the future will not just be a traditional artist; they will be a new kind of engineer who can use the power of a digital file to create a physical object.

Conclusion

In conclusion, 3D printing is not a passing trend; it is a transformative paradigm that is fundamentally reshaping our approach to product design and manufacturing. By leveraging the power of additive manufacturing, a direct-to-digital workflow, and a new kind of complex geometry, we are moving beyond a world of a mass-produced, one-size-fits-all product and into a new era of a personalized, custom-made, and on-demand one. The foundational principles of this revolution are all working in synergy to create a new way of living and working. The applications of this technology are incredibly diverse and profound, promising to revolutionize everything from rapid prototyping and personalized prosthetics to a new, more sustainable approach to manufacturing.

The promise of 3D printing is immense. It offers a solution to some of the most pressing challenges of our time, from the inefficiencies of traditional manufacturing to the waste generated by a culture of excess. It holds the potential to create a future where our products are not just a collection of mass-produced objects, but a reflection of our most personal and our most unique selves. This is not just a technological upgrade; it is a blueprint for a better and more human-centered future, one where we can use the power of design to create a world that is more innovative, more sustainable, and more equitable.

However, as we embrace this new era, we must also be mindful of the challenges that lie ahead. The issues of materials, strength, and intellectual property are not footnotes; they are central to the responsible development of 3D printing. We must navigate this path with a new ethical framework, one that ensures that this powerful design philosophy is used to empower humanity, not to control or exploit it. The 3D printing revolution is a journey that will be defined not just by what we can create, but by what we do with the opportunity to build a new, more personal, and more sustainable world. The future is a reflection of the products we design today, and the most exciting part of this journey is that we are all a part of it.